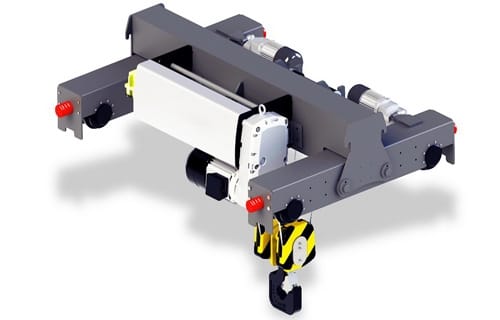

WH electric chain hoist

design and fabricate according to FEM/DIN standard

high security

high reliability

high efficiency

modular design

humanization design

maintenance free

High security

--Mechanical overload limiter, elastic torque limiter, limit switches and friction clutch combined into a comprehensive security system to ensure the operator and product safety.

--Implementation of safety monitoring system can be installed to achieve product running condition monitoring, maintenance information display, and fault diagnosis, to ensure product safety.

German imported chain, safety factor of 5 to ensure safe operation.

German imported high-strength hook, in line with the German DIN15401 standards, with safety tabs to ensure safe operation.

Traveling trolley fall protection designed to ensure safe operation.

Control cable with anti- pull-off wire.

High efficiency

--Maximum lifting weight can reach 5t, maximum lifting height up to 120m, which can be more widely used.

--maximum lifting speed can reach 10m / min ( non-standard design up to 16m / min); manual trolley uses a patented design , smooth pull-out style ; electric trolley maximum operating speed of up to 20m / min, with diverse and flexible rate combination , machine efficiency increased from 25 to 40 percent compared to conventional products ;

--Running gear: select electric or manual mechanism according to needs. Electric running gear can be used in two different speeds.

Modular design

--Aluminum casing, through finite element analysis to optimize the design, form a standard modular series, small size, light weight, high strength, easy to assembly, sealing well.

--Using standard series of German import drive module, and contributed to rich product series with a different pulley ratio;

--Chain hoist for different application environments, product design different installation form, and can be a standard part of the way through the replacement switch freely (hang shank hook, manual trolley, electric trolley -style freely combined in different ways)

--Electrical interfaces adopt aluminum alloy standard plug-in, safe and convenient;

--Hanger detachable design;

Humanization design

--Sprocket uses plug-in connectors for quick replacement of the entire sprocket without disassembling the motor or gear parts, thus greatly reducing downtime and easy for maintenance.

--The electric door which is equipped with emergency stop switch is more secure and simple to operate. Its User-friendly design meets the ergonomic principle and has moderate operating sensitivity. The good operation hand feeling can reduce fatigue operation.

--Ergonomically designed hook improves security and controllability.

-- The reducer uses sophisticated gear grinding process, hardened self-lubricating quiet and low noise design. The specially designed chain belt / chain box with imported chain effectively reducing the noise, the noise level below 60dB.

Maintenance free

--First electric plug braking then rely on brake to make the brake more quickly and smoothly, and also greatly reduces brake wear. Due to the small wear, there’s no need to adjust the brake and improves the life and reliability; maintenance-free for 10 years.

--Reducer adopts a 10 -year maintenance-free design and has two-stage helical gears, gear precision more than seven, low noise, smooth operation. The iron reducer installed an internal magnet for attracting scrap iron and reducing gear wear. Reducer adopts sealing design, no drain and ventilation holes; mineral oil lubricate, free replacement for 10 years.

--Friction clutch automatically controls shutdown through the speed detection device when slip to thoroughly prevent severe wear or damage caused by prolonged load friction clutch slippage. Since reaching the lowest wear, friction clutch can realize maintenance-free for 10 years without having to make any adjustments.

.png)

English

English.jpg)