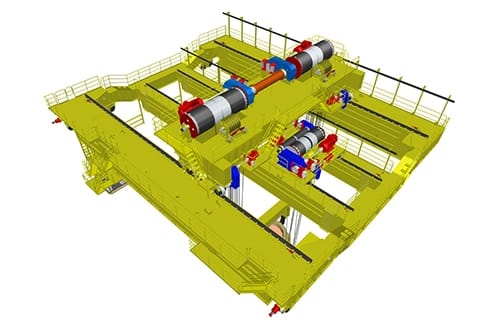

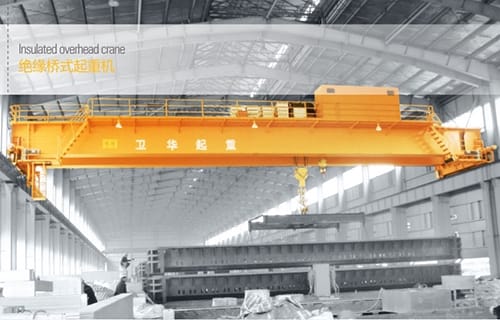

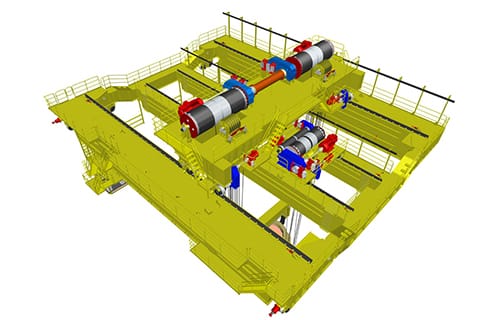

Quenching Crane

With the development of electric power generation equipment, petroleum, chemicals, heavy machinery and higher quality requirements for large forgings in the part of users, the quality of heat treatment technology and equipment should be improved correspondingly, so does the size of quenching crane used for lifting heavy forgings.

|

Quenching Ladle Crane Technical Specifications |

|||||||||

|

Capactiy(t) |

Span (m) |

Lifting Height |

Work Duty |

Main Lifting Speed |

Aux Lifting Speed |

Crab Travelling Speed |

Trolley Travelling Speed |

Power (kw) |

Rail |

|

5 |

10.5~16.5 |

16 |

A7 |

12.9 |

- |

39.5 |

93.7 |

24.5 |

43kg/m |

|

19.5~31.5 |

95.2 |

27.1 |

|||||||

|

10 |

10.5~22.5 |

20 |

13 |

- |

35.2 |

95.2 |

40.1 |

||

|

25.5~31.5 |

88.3 |

45.5 |

|||||||

|

16/3.2 |

10.5~16.5 |

16/18 |

10.9 |

11.5 |

31 |

87.8 |

54.3 |

43kg/m |

|

|

19.5~31.5 |

90.4 |

59.7 |

|||||||

|

20/5 |

10.5~16.5 |

12/14 |

9.8 |

12.7 |

37 |

88.3 |

71.7 |

||

|

19.5~31.5 |

90.9 |

79.7 |

|||||||

|

32/5 |

10.5~16.5 |

16/18 |

7.7 |

12.7 |

37.6 |

90.9 |

90.5 |

QU70 |

|

|

19.5~31.5 |

77 |

90.5 |

|||||||

|

50/10 |

10.5~16.5 |

12/16 |

6.3 |

10.5 |

31.8 |

77 |

118.5 |

QU80 |

|

|

19.5~31.5 |

77.8 |

130.5 |

|||||||

|

74/20 |

13.5~19.5 |

20/22 |

6.4 |

9.7 |

37.2 |

67.4 |

200 |

QU100 |

|

|

22.5~31.5 |

77 |

214 |

|||||||

|

100/32(Double Girder) |

19.5~28.5 |

20/22 |

7.5 |

10.5 |

38 |

68 |

393 |

QU120 |

|

|

100/32(Four Girder) |

19~28 |

20/22 |

7.5 |

12 |

32.5/37.4 |

78 |

426.5 |

||

|

125/32(Double Girder) |

19.5~28.5 |

20/22 |

7.5 |

10.5 |

38 |

79.7 |

479 |

||

|

125/32(Four Girder) |

19~28 |

20/22 |

7.5 |

12 |

38/37.4 |

79.7 |

484.5 |

||

|

140/40(Double Girder) |

22~28 |

22 |

6.8 |

9.1 |

38 |

73 |

479 |

||

|

140/40(Four Girder) |

22~28 |

22 |

6.8 |

9.6 |

38 |

77.8 |

510.5 |

||

|

160/40(Four Girder) |

22~28 |

22 |

0.6~6 |

9.5 |

38 |

77.8 |

|

||

|

180/50(Four Girder) |

28.5 |

27/29 |

7.2 |

9.3 |

38/40 |

86 |

|

||

|

200/50(Four Girder) |

28 |

26 |

8 |

9.3 |

40 |

86 |

|

||

|

225/65(Four Girder) |

27 |

28 |

8 |

10 |

40/38 |

87 |

|

||

|

240/75(Four Girder) |

24 |

30 |

|||||||

English

English.jpg)